Beryllium Copper B25 B7 B14 B8 B33 strips / wire/ plate/ rod used in electronic industry

Copper-beryllium alloys are mainly based on copper with a beryllium addition. High strength beryllium copper alloys contain 0.4-2% of beryllium with about 0.3 to 2.7% of other alloying elements such as nickel, cobalt, iron or Lead. The high mechanical strength is achieved by precipitation hardening or age hardening.

Beryllium Copper is a copper alloy with the optimum combination of mechanical and physical properties such as tensile strength, fatigue strength, performance under elevated temperatures, electrical conductivity, bending formability and corrosion resistance. Beryllium Copper is widely used as contact springs in various applications like connectors, switches, relays, etc.

Chemical Composition

Typical Physical Properties

Mechanical property (Before Hardening treatment) :

After Hardening treatment

Features

1. High thermal conductivity

2. High corrosion resistance, especially suitable for polyoxyethylene (PVC) products mold.

3. High hardness, wear resistance and toughness, as inserts used with mould steel and aluminium can make the mold play a highly efficient, prolong the service life.

4. Polishing performance is good, can achieve high mirror surface precision and complicated shape design.

5. Good tackiness resistance, easy to welding with other metal, easy to machining, there is no need additional heat treatment.

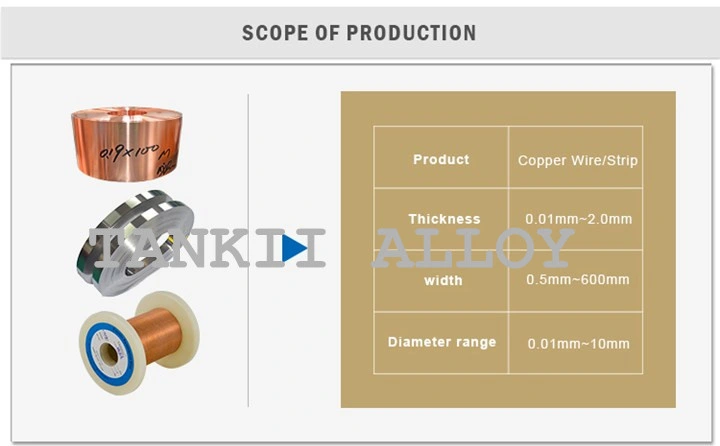

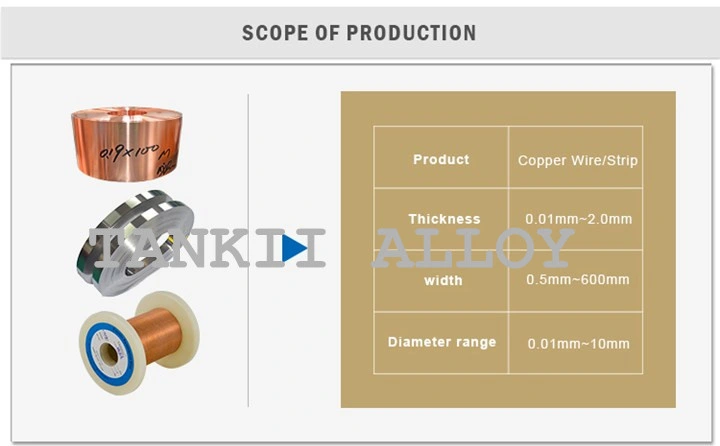

Our product are in the form of wire, ribbon, strip, coil.

Round wire

Ribbon (flat wire)

Strip / foil

Stranded wire

Sheet / plate

Applications

Automotive, electronic, aeronautical, Oil&Gas, watch, electro-chemical industries, etc. Beryllium Copper is widely used in those fields as contact springs in various applications like connectors, switches, relays, etc.

Copper-beryllium alloys are mainly based on copper with a beryllium addition. High strength beryllium copper alloys contain 0.4-2% of beryllium with about 0.3 to 2.7% of other alloying elements such as nickel, cobalt, iron or Lead. The high mechanical strength is achieved by precipitation hardening or age hardening.

Beryllium Copper is a copper alloy with the optimum combination of mechanical and physical properties such as tensile strength, fatigue strength, performance under elevated temperatures, electrical conductivity, bending formability and corrosion resistance. Beryllium Copper is widely used as contact springs in various applications like connectors, switches, relays, etc.

Chemical Composition

| Element | Component |

| Be | 1.85-2.10% |

| Co+Ni | 0.20% Min |

| Co+Ni+Fe | 0.60% Max. |

| Cu | Balance |

Typical Physical Properties

| Density (g/cm3) | 8.36 |

| Density before age hardening (g/cm3 | 8.25 |

| Elastic Modulus (kg/mm2 (103)) | 13.40 |

| Thermal Expansion Coefficient (20 °C to 200 °C m/m/°C) | 17 x 10-6 |

| Thermal Conductivity (cal/(cm-s-°C)) | 0.25 |

| Melting Range (°C) | 870-980 |

Mechanical property (Before Hardening treatment) :

| status | Tensile strength (Kg/mm3) | Hardness (HV) | Conductivity ( IACS%) | Elongation (%) |

| H | 70-85 | 210-240 | 22 | 2-8 |

| 1/2H | 60-71 | 160-210 | 22 | 5-25 |

| 0 | 42-55 | 90-160 | 22 | 35-70 |

After Hardening treatment

| Brand | Tensile strength (Kg/mm3) | Hardness (HV) | Conductivity (IACS%) | Elongation (%) |

| C17200-TM06 | 1070-1210 | 330-390 | ≥17 | ≥4 |

Features

1. High thermal conductivity

2. High corrosion resistance, especially suitable for polyoxyethylene (PVC) products mold.

3. High hardness, wear resistance and toughness, as inserts used with mould steel and aluminium can make the mold play a highly efficient, prolong the service life.

4. Polishing performance is good, can achieve high mirror surface precision and complicated shape design.

5. Good tackiness resistance, easy to welding with other metal, easy to machining, there is no need additional heat treatment.

Our product are in the form of wire, ribbon, strip, coil.

Round wire

Ribbon (flat wire)

Strip / foil

Stranded wire

Sheet / plate

Applications

Automotive, electronic, aeronautical, Oil&Gas, watch, electro-chemical industries, etc. Beryllium Copper is widely used in those fields as contact springs in various applications like connectors, switches, relays, etc.