1045 12L14 4140 cold finished steel round bar hexagon bar flat bars

COLD FINISHED CARBON STEEL BAR TECHNICAL INFORMATION

Selected Cold Finished Steel Bar Characteristics

Low Carbon - Case Hardening1018, 1020 -- A low carbon steel with a medium manganese content. Has good hardening properties, fair machinability. Readily grazed and welded. Suitable for shafting and for applications that do not require the greater strength of high carbon and alloy steels. Conforms to ASTM A-108 and AMS 5069.

Medium Carbon - Direct Hardening

1040, 1045 -- Medium carbon steels used when greater strength and hardness is desired in the as-rolled condition. Can be hammer forged and responds to heat treatment. Suitable for flame and induction hardening. Uses include gears, shafts, axles, bolts and studs, machine parts, etc.

Medium Carbon Alloy Bars -- Direct Hardening

The medium carbon and direct hardening steels in this group offer you the right combination of strength, toughness and hardness after oil quenching and tempering -- plus machinability. When increased wear resistance is required in localized areas, they can be flame or induction hardened. Hardenability data is developed for each heat of steel and furnished with the heat's certification document.

4140/4150 -- are widely used medium carbon steels -- truly general purpose alloys, low in cost. Nominal composition: .95% chromium and .20% molybdenum content. A broad range of strength and toughness is attainable through variations in heat treatment. Good hardenability, strength, wear resistance, toughness and ductility.

41L40 -- is a superior free machining direct hardening alloy. A chrome moly alloy with 40% carbon and 15%/35% lead addition can be quenched an tempered to a broad range of strength levels.

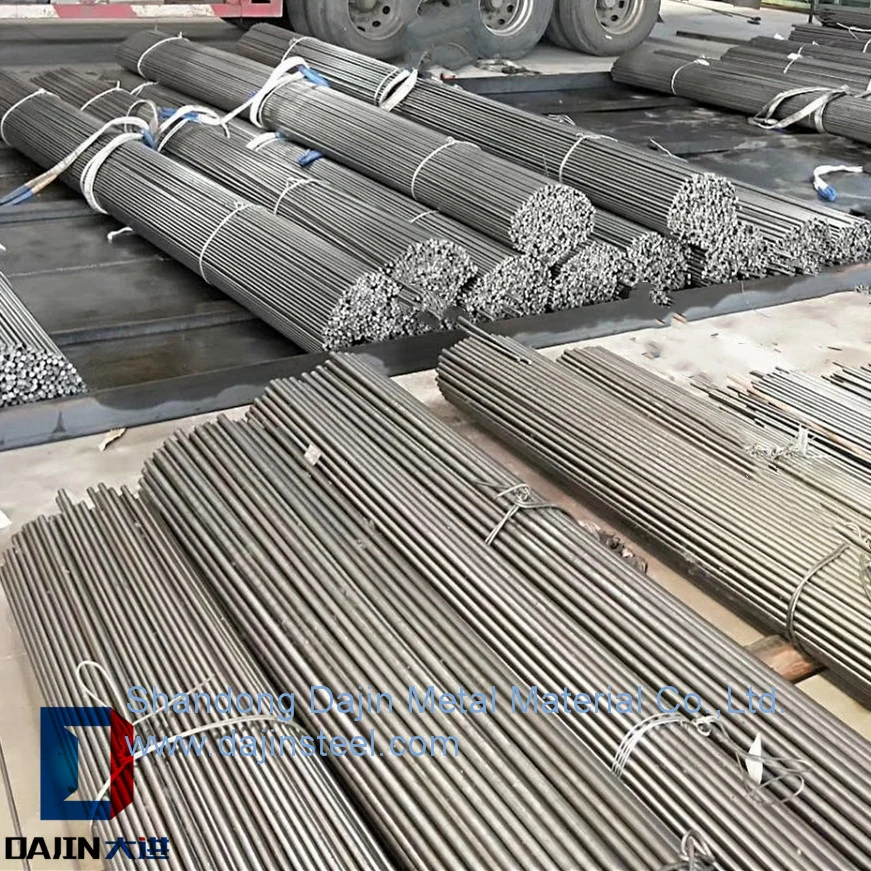

Packaging Available Upon Request

- Small Steel Banded Bundles: 3,000# - 3,999# and 2,000# - 2,999#

- Extra Steel Bands for Bundles

- Wooden Boxing (to ensure straightness and surface protection) -- 2,000# and 1,000# capacities per box

- Paper or Plastic Wrapped Bundles to protect steel from environmental conditions

Selection Tips

For many applications cold finished steel bars are selected in preference to hot rolled bars because of their better finish or closer size accuracy. All cold finish steel bars have these advantages - in varying degrees of course. And it's simple enough to select a type for your job if these properties alone are needed. But many times selection involves additional factors - and the following quick facts should help you get maximum performance at lowest overall cost:Machinability. All drawn bars machine better than hot rolled. If the prime requirement is machinablitiy, the leaded steels provide maximum production of machined parts at lowest cost per piece.

Minimum Warpage. When bars are cold drawn through a die, strains are set up in the steel. Unless relieved, warpage may occur as soon as the bars are machined. Turned bars, however, may be machined or keyseated with practically no danger of warpage.

Strength. Drawn bars have a 10 - 20% greater strength in the areas affected by cold drawing. There is no increase in strength when hot rolled bars are turned. The higher carbon steels are frequently selected for more strength.

Main grade

| Steel grades | C | Si | Mn | Cr | Mo | Ni | P | S | V | w | |

| Carbon Structure Steel | Q235(B)/SS400/S235JR/A36 | ≤ 0.20 | ≤0.35 | ≤1.4 | 0.3-0.4 | ≤0.30 | ≤ 0.045 | ≤ 0.045 | |||

| 20#/CK22, CK20/1020/050A20/S20C | 0.17-0.23 | 0.17-0.37 | 0.35-0.65 | 0.3-0.4 | ≤0.30 | ≤ 0.035 | ≤ 0.035 | ||||

| 45#/CK45, C45/1045/080M46/S45C | 0.42-0.5 | 0.17-0..37 | 0.5-0.8 | 0.3-0.4 | ≤0.30 | ≤ 0.035 | ≤ 0.035 | ||||

| Alloy Structure Steel | 20Cr/20Cr4/5120/527A19/SCr420H | 0.18-0.24 | 0.17-0.37 | 0.50-0.80 | 0.70-1.00 | ≤0.15 | ≤0.30 | ≤ 0.035 | ≤ 0.035 | ||

| 40Cr/41Cr4/5140/520M40/SCr440 | 0.37-0.44 | 0.17-0.37 | 0.5-0.8 | 0.8-1.1 | ≤0.15 | ≤0.30 | ≤ 0.035 | ≤ 0.035 | |||

| 30CrMo/4130/1717COS110/SCM420 | 0.26-0.34 | 0.17-0.37 | 0.4-0.7 | 0.8-1.1 | 0.15-0.25 | ≤0.30 | ≤ 0.035 | ≤ 0.035 | |||

| 35CrMo/34CrMo4/4135/708A37 | 0.32-0.40 | 0.17-0.37 | 0.4-0.7 | 0.8-1.1 | 0.15-0.25 | ≤0.30 | ≤ 0.035 | ≤ 0.035 | |||

| 42CrMo/42CrMo4/4140/708A42/708M40 | 0.38-0.45 | 0.17-0.37 | 0.5-0.8 | 0.90-1.2 | 0.15-0.25 | ≤0.30 | ≤ 0.035 | ≤ 0.035 | |||

| 8620H | 0.17-0.23 | 0.15-0.35 | 0.65-0.95 | 0.35-0.65 | 0.15-0.25 | 0.35-0.75 | ≤0.025 | ≤ 0.035 | |||

| 40CrNiMoA/40CrNiMo22/4340/871M40/SNCM439 | 0.37-0.44 | 0.17-0.37 | 0.50-0.80 | 0.60-0.90 | 0.15-0.25 | 1.25-1.65 | ≤ 0.025 | ≤ 0.025 | |||

| Spring Steel | 55Si2Mn/55Si7/9255/250A53/SUP6 | 0.52-0.60 | 1.50-2.00 | 0.60-0.90 | ≤0.35 | ≤0.35 | ≤ 0.035 | ≤ 0.035 | |||

| 60Si2MnA/65Si7/9260/250A61/SUP7 | 0.56-0.64 | 1.60-2.00 | 0.70-1.00 | 0.3-0.4 | ≤0.35 | ≤ 0.025 | ≤ 0.025 | ||||

| 50CrVA/50CrVA/6150/735A50/SUP10 | 0.47-0.54 | 0.17-0.37 | 0.50-0.80 | 0.80-1.10 | ≤0.15 | ≤0.30 | ≤ 0.025 | ≤ 0.025 | |||

| GCr15/100Cr6/E52100/534A99/SUJ2 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 1.40-1.65 | ≤0.10 | ≤0.30 | ≤ 0.025 | ≤ 0.025 | |||

| Bearing Steel | 52100 | 0.93-1.05 | 0.15-0.35 | 0.25-0.45 | 1.35-1.60 | ≤0.10 | ≤0.25 | ≤ 0.025 | ≤ 0.015 |