Product Description

High Quality Gasketed Plate Heat Exchanger

Product Characters

EFFICIENT

EFFICIENTHigh heat transfer coefficiency -- corrugated stainless steel plate and counter flow style

Maximum heat transfer coefficient: 7000W/m2K

CUSTOM-MADE

CUSTOM-MADEWide selection of materials -- plates(SS304, SS316L, SMO254,Ti,Ni,Hastelloy), gaskets(NBR, EPDM, HNBR, Fluororubber/Viton, Silicon)

Multi-media available -- water to water(fluid to fluid), steam to water(gas to fluid)

According to various applications, we will design the optimal product for your requirements

CONVENIENT

CONVENIENT Easy cleaning -- smooth surface, detachable plates

Small floor area -- compact size

RELIABLE

RELIABLE 15-year experience in heat exchanger and pressure vessel

2 production bases -- Guangzhou; Hubei

Strong technical team -- 5 senior engineers (over 20 years experience)

Quality guaranteed -- CE,SGS,ISO9001 certified, 18 patents

Warranty -- 1 year guarantee

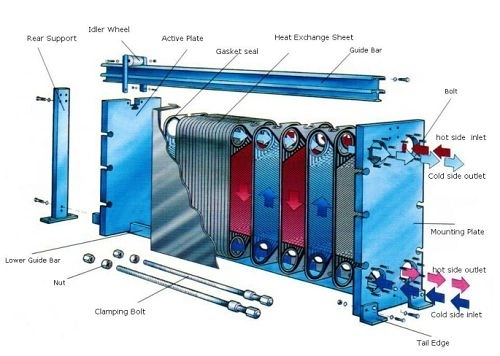

How It Works

As a new efficient and compact heat exchanger, this product consists of multiple parallel corrugated-surface thin metal sheets that overlap and are then fixed by lamp plates and bolts.

Heat exchange principle: the cold working fluid and the hot working fluid flow through the narrow and winding passage made of two neighboring plates alternately and realize cold and heat exchange through the plates separating the two working fluids.

Plates and Gaskets

The plate heat exchanger's plate materials and corresponding applicable places are given in Table 1 and its gasket materials and corresponding applicable places in Table 2 for your reference.

Table 1

Plate Materials

| Material name | Thickness(mm) | Material grade | Applications |

| Stainless steel | 0.5-0.8 | 304,321,316,316L | Places with serious corrosion caused by acid or base mediums and places not suitable for chloride ions |

| Commercial pure titanium | 0.5-0.8 | Ti | Alkali or salt making places, sea water desalination places, low-temperature places, freezing places or places with chloride-ion corrosion |

| Nickel | 0.5-0.8 | Ni | Places resistant to corrosion, hot alkali liquor corrosion, neutral solutions or subacid solutions |

| Acid-resistant steel | 0.5-0.8 | RS-2, SM0254, HC-276 | Sulfuric acid field and the fields with acid corrosion |

Table 2

Gasket Materials

| Material name | Code | Applicable temperature | Applications |

| NBR | N | -20~110ºC | Water, non-polar oil, mineral oil, lubricating oil, silicon oil, etc. |

| EPDM | E | -20~150ºC | Steam, water, ozone, polar chemical mediums, alcohol, weakacids, weak bases, salt solutions, etc. |

| Chloroprene rubber | C | -40~100ºC | Ammonia, mineral roil, lubricant, freon, etc. |

| Fluororubber | F | 0~180ºC | Inorganic acids, bases, mineral oil, halohydrocarbon and oxidant |

| Silicon rubber | Q | -40~200ºC | Food field, etc. |

For more information, feel free to contact us !

Contact Person: Shirley